HKAA-professional custom CNC machining parts manufacturer with quality CNC machining centers

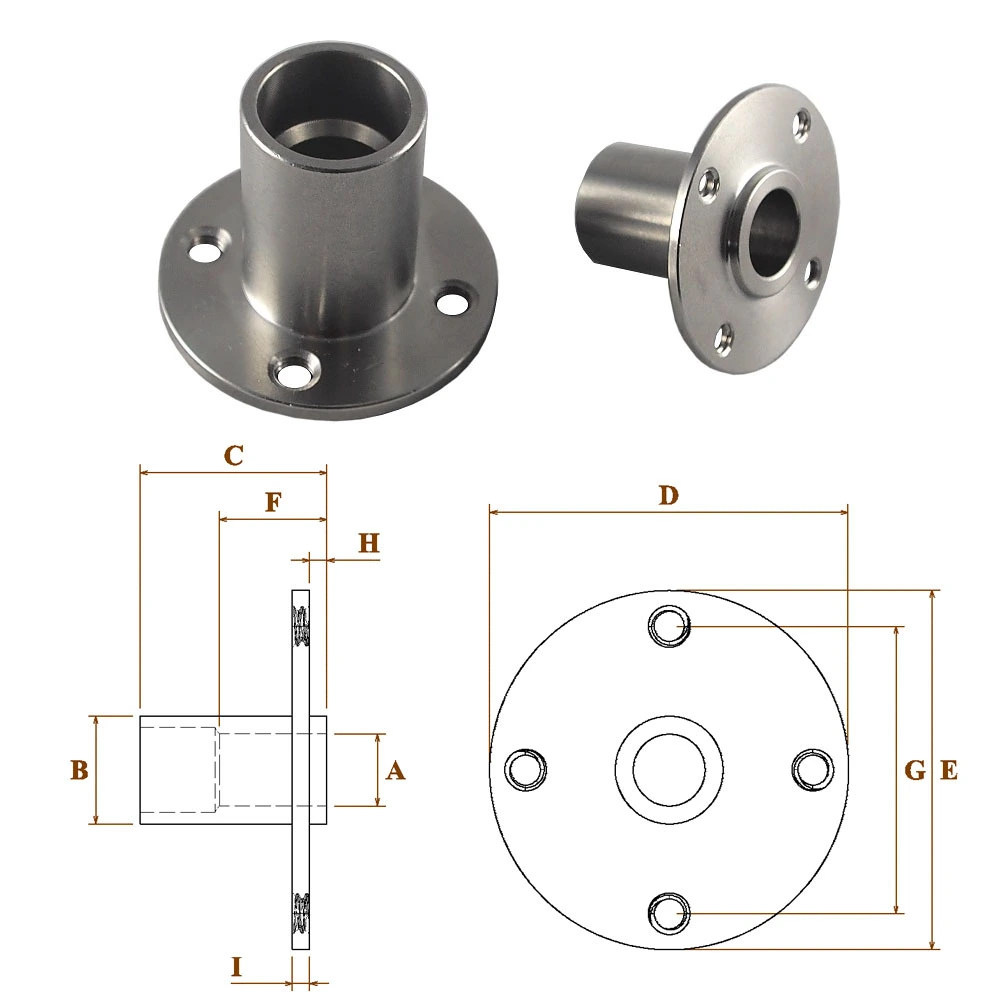

Locating Bushings with flange for ball lock pins and socket pins

Our Pin Receptacle range has three different styles to choose from; Circle, Diamond and Oval Pin Receptacles. They feature a large flange, and allow for a blind hole to accommodate our standard Quick-Release Pins.

When your ball lock pin does not have a surface to lock against, these receptacles can be used as a permanent mating hole. The receptacle mounting hole size is 6-32, except when 1/2 inch, the diameter is 10-32.

The Pin Receptacles are made of Stainless Steel that offers a low maintenance, easy to clean and generally more hygienic option compared to Low Carbon Steel. The Stainless Steel is highly recyclable and provides excellent corrosion resistance for applications that might involve a salt environment.

Other configurations, materials, and customizations are available upon request.

Product Details

Product Description

--When the pin doesn’t have a surface to lock against, use this receptacle for a permanent mating hole.

--Receptacle mounting hole size is 6-32, except 1/2” diameter is 10-32. or Customized

--Material is stainless steel and Customization is available.

--For use with a wide variety of quick release pins for extra secure retention.

--Used in applications where a suitable mating hole is not available

--Works great as a quick easy fix when mating holes have become oversized.

Locating bushings are used for quick and safe location of single acting ball lock pins - especially in soft materials such as aluminium, or in thin walled components.Used for thin sheet materials, e.g. in vehicle construction, apparatus engineering, container construction and the aviation industry.

Can be used from both sides. Optimised centering due to precision collar on bush.

The bearing surface of the flange ensures optimum force distribution at components with thin walls.

All versions are corrosion and abrasion resistant.

Product Application

FAQ

B: COC

C: Material cert

D: Some parts with hardness test report

E: some parts with salt spray test report

Do You Have Any Questions? Contact Us Now.

We can offer a one-stop station service, and support the latest in CNC machining and turning processes, can support a high level of part complexity, and provide exceptional surface finishes.