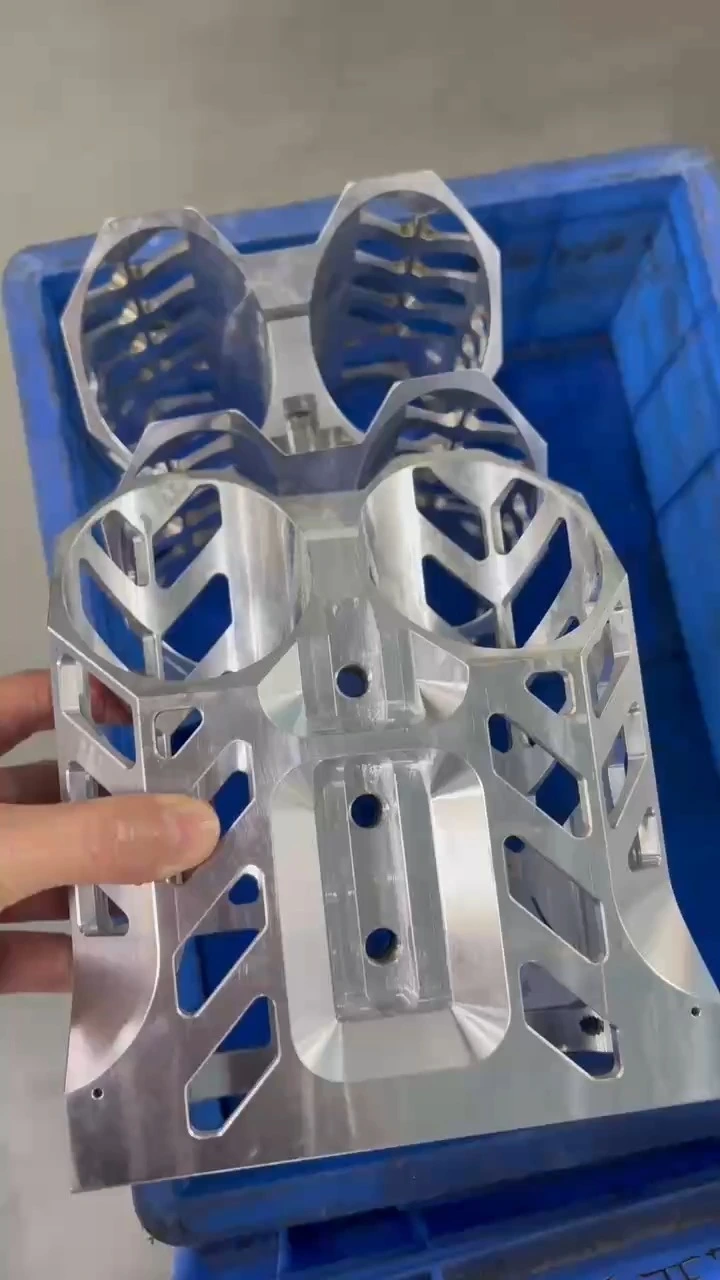

HKAA-professional custom CNC machining parts manufacturer with quality CNC machining centers

CNC machining of aluminum for jetski handle poles

In the realm of metalworking, CNC machining technology stands as a revolutionary powerhouse in the manufacturing of aluminum parts, especially when it comes to producing the crucial handle poles for jetskis. Its advantages are simply irreplaceable.

Leveraging precise programming and automated operations, CNC machining meticulously crafts aluminum materials into handle poles that meet the most stringent standards. Thanks to its high - precision machining, the dimensional errors of all components of the handle pole are minuscule, ensuring a perfect fit. This results in incredibly sensitive and accurate steering, allowing riders to effortlessly navigate their jetskis on the water, fully enjoying the thrill and passion of high - speed rides.

Aluminum handle poles processed by CNC machining feature a mirror - smooth surface. Paired with processes like anodizing, they not only flaunt a stylish and eye - catching appearance but also significantly enhance their wear and corrosion resistance, greatly extending their service life. Whether for leisurely cruising or intense racing, these handle poles perform stably and reliably, becoming indispensable high - quality components of jetskis.

HK AA specializes in custom - made aluminum jetski pole parts, offering anodizing coloring manufacturing, CNC machining services, and a wide range of jetski accessories.

CNC sculpts aluminum to form crucial jetski handle poles

Jetski handle poles: key parts of CNC aluminum machining

CNC machining of aluminum parts creates the crucial handle poles for jetskis.

Do You Have Any Questions? Contact Us Now.

We can offer a one-stop station service, and support the latest in CNC machining and turning processes, can support a high level of part complexity, and provide exceptional surface finishes.